# Drone Inspection of Underground Canals for River Management

## Key Benefits at a Glance

While traditional 2D maps were the sole reference, our team utilized the Elios 3 drone to conduct inspections at low tide, accessing underground canals that might not have been explored since their construction. This approach ensured a safe and efficient drone river inspection.

| Feature | Description |

|-----------------|-----------------------------------------------------------------------------|

| Access | The Elios 3 provided access to previously unreachable areas, enabling us to gather critical data safely. |

| Data Quality | High-quality visual data, including photos and videos, along with a detailed LiDAR scan, exceeded client expectations. |

| Safety | Sending personnel into such environments is extremely risky due to unpredictable water levels and currents. The drone eliminated these dangers. |

| Speed | All data collection was completed in just one day, drastically reducing the time required compared to conventional methods. |

*Modern drone technology, like the Elios 3 shown here, is revolutionizing how we access and inspect complex or confined spaces.*

## Planning a Drone River Inspection Mission

Sater, a leading company based in northern France near Lille, specializes in water and wastewater management. As part of the SARP group, which is a subsidiary of Veolia, Sater has over three decades of experience in delivering innovative solutions across France. Their team of 115 professionals is dedicated to tackling intricate inspection challenges that traditional methods cannot address.

Recognizing the potential of drone technology in water management, Sater recently invested in an Elios 3 drone. This acquisition marked a significant step forward in their ability to perform safe and effective inspections. Recently, Sater deployed the Elios 3 in Rouen to assess underground canals prior to a major construction project.

## Inspecting Canals Using Drones

Rouen’s Marché d'Intérêt National (MIN) features a river running beneath its buildings and connecting streets, eventually emptying into the Seine. Plans are underway to construct new facilities above ground, but first, the integrity of the water network beneath must be verified. Divers were ruled out due to the inherent risks, including unpredictable water levels and strong currents. While some ROVs could potentially reach these spaces, they may struggle with the current or become stuck.

This scenario highlighted the need for a safer, more efficient solution—enter the Elios 3.

*The Elios 3 drone was instrumental in navigating and mapping these challenging underwater environments.*

## Executing the Drone River Inspection

The Sater team faced the challenge of conducting inspections with limited historical data, as the canal had never been inspected since its construction. The mission was scheduled for early April, timed precisely to coincide with the lowest possible tidal coefficients.

Each tunnel measured 3 meters in diameter and stretched 540 meters underground, with manholes spaced approximately every 50 meters. Navigating through these tight spaces required precise planning and execution.

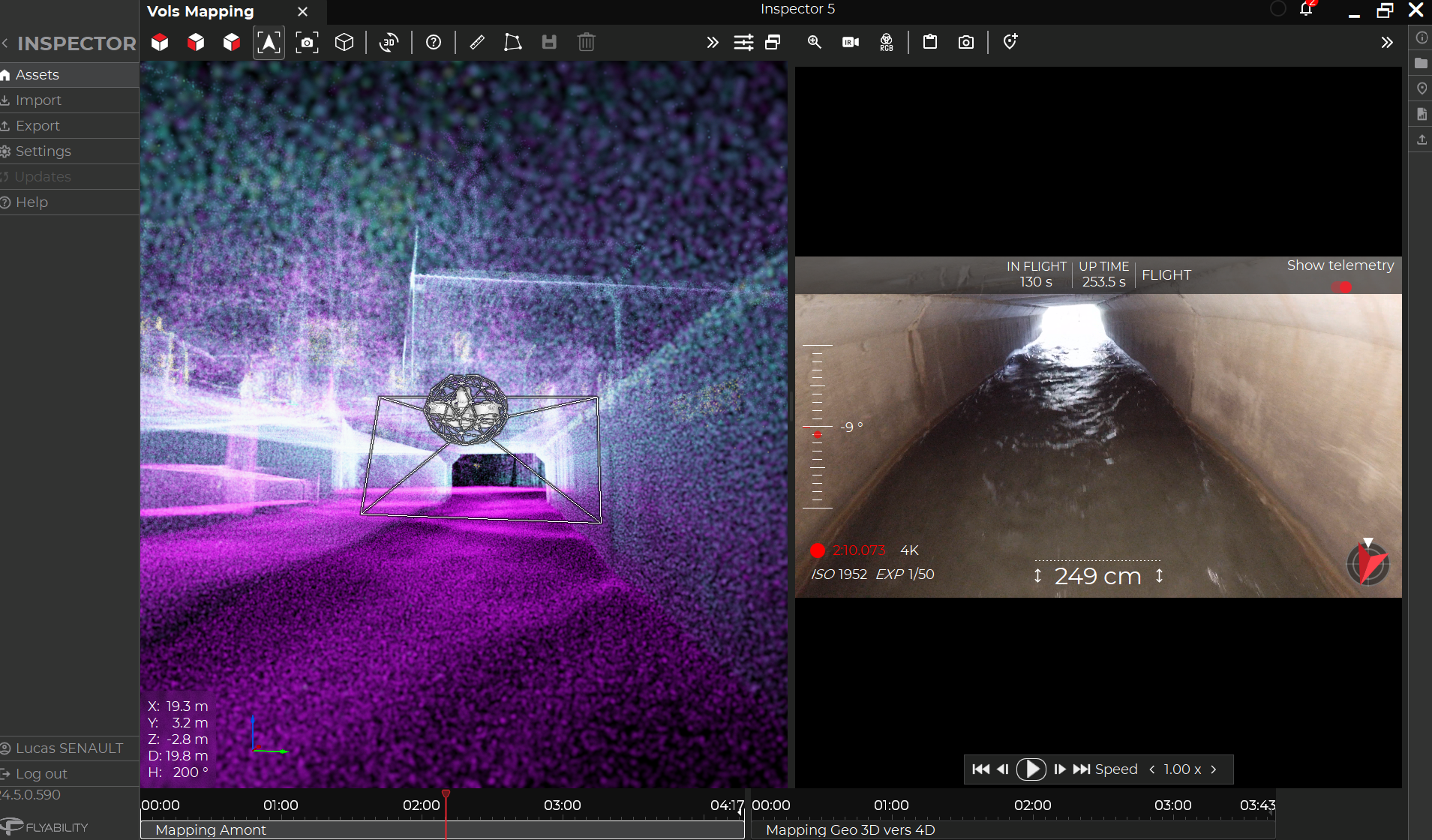

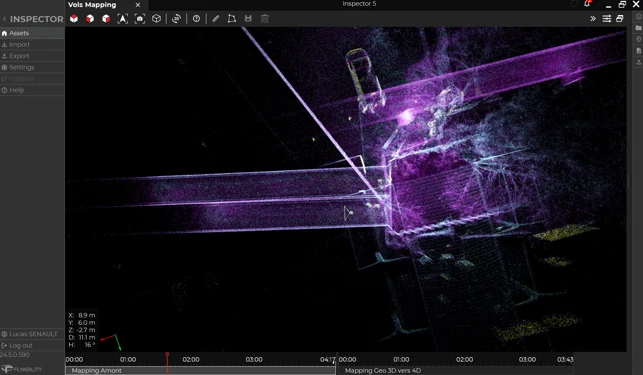

Using the drone’s visual camera and LiDAR capabilities, the team successfully mapped the interior of both tunnels. Despite the limited visibility, the Elios 3 performed flawlessly, allowing the pilots to guide the drone safely even when it was out of sight.

*The LiDAR scan created a comprehensive 3D model of the tunnels, offering unparalleled insights into their condition.*

## Delivering Value Through Advanced Technology

The primary goal of the inspection was to capture high-resolution video footage of the interior of the pipes. However, the inclusion of LiDAR scanning proved to be a game-changer. The resulting 3D model was both accurate and visually striking, providing the municipality with a clear picture of the canal’s condition without risking human lives.

*The LiDAR scan transformed raw data into actionable insights, facilitating better decision-making for future urban development.*

This project not only satisfied the immediate needs of the client but also positioned Sater as a pioneer in utilizing advanced drone technology for complex inspections. By pushing the boundaries of what’s possible with the Elios 3, Sater has paved the way for even more ambitious initiatives in the future.

In conclusion, this drone river inspection demonstrated the immense potential of modern drone technology in addressing previously insurmountable challenges. The Elios 3 proved to be an invaluable asset, ensuring safety, efficiency, and superior data quality—all within a remarkably short timeframe.

304 Stainless Steel Wire Mesh

304 stainless steel mesh is

mainly used for acid, alkali environmental conditions under screening and

filtration, petroleum industry for mud mesh, chemical fiber industry for screen

mesh, electroplating industry for pickling mesh, gas, liquid filtration and

other media separation. Generally, stainless steel mesh, nickel

wire, brass wire as the material. The metal wire braiding in the

weft wire dense arrangement, plain weave, twill weave, plain Dutch weave, twill

Dutch weave, reverse Dutch weave five methods.

Material: stainless steel

mesh, nickel wire, brass wire. Mainly used for gas, liquid

filtration and separation of other media.

Stainless steel is

resistant to heat, acid, corrosion and wear. Because of these

characteristics, Stainless Steel Wire Mesh is widely used in mining, chemical,

food, medicine and other industries.

304 Stainless Steel Wire Mesh,Ss 304 Wire Mesh Price,304 Stainless Steel Mesh,304 Ss Mesh

Suzhou Haoxiang Screen Stencil Products Co.,Ltd , https://www.haoxiangwiremesh.com