Elios 3 Stockpile Measurements Improve Safety & Accuracy at Salt Mine

Elios 3 Enhances Safety and Precision in Salt Mine Stockpile Assessments

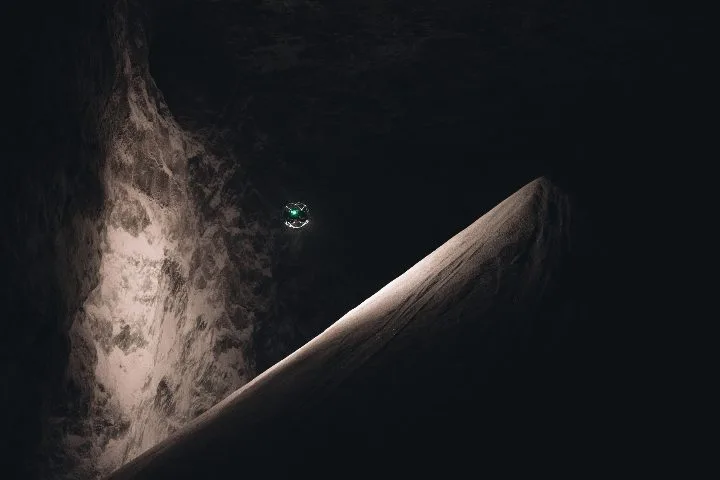

Data gathered via LiDAR from the Elios 3 enabled mining engineers at a German salt mine to perform stockpile measurements with enhanced precision and safety.

Key Benefits at a Glance

|

Efficiency Manually calculating salt stockpile volumes is labor-intensive and time-consuming. With the Elios 3, mining surveyors can stay in one spot while flying the drone through the area, creating precise 3D models of the stored salt. This drastically cuts down on the time required for data collection. |

Precision Compared to traditional manual methods, the Elios 3 generates highly accurate 3D models. These models provide far more reliable data for stockpile calculations, ensuring more informed decision-making. |

Safety Surveyors traditionally face risks when climbing salt stockpiles to gather data. The Elios 3 eliminates this danger by allowing surveyors to collect all necessary data from a safe distance, remaining grounded while flying the drone through the stockpile area. |

Introduction

Accurate volume calculations are critical in the mining industry, especially for managing stockpiles of materials like salt that are amassed over time. These calculations play a key role in determining:

-

The amount of material currently available in stockpiles within a mine.

-

The volume of material being transferred in or out of storage.

-

The quantity of material needed to backfill chambers after extraction, helping ensure proper balance between removal and replenishment.

Currently, most volume assessments rely heavily on manual methods, such as surveyors scaling stockpiles to take physical measurements or using handheld sensors to gauge heights. While weighing trucks provides some insight into material movement, these approaches often yield imprecise results due to human error and environmental factors. Despite the inefficiencies and inaccuracies inherent in manual processes, they remain standard practice because they are seen as necessary despite their drawbacks.

Customer Challenges

At a prominent salt mine in Germany, the surveying team is tasked with maintaining comprehensive maps of the entire mine, including detailed inventories of salt stockpiles stored in various chambers. Conducting monthly surveys of these stockpiles is essential for tracking inventory levels and planning future operations.

Traditionally, this process involves two full shifts of work: one for manual data collection, during which surveyors climb the salt piles to measure their heights, and another for processing the data into usable information. This method is physically demanding, requiring surveyors to be in excellent physical condition to navigate steep, uneven surfaces safely. Additionally, the manual nature of the process introduces significant room for error, leading to less-than-reliable data.

To capture data, surveyors ascend the salt cones and measure vertical distances from the pile tops to the ceiling above. After gathering these readings, they input them into CAD software to generate visual representations of the stockpiles, which are then used to compute volumes. While this approach provides some level of insight, it is both time-consuming and prone to inaccuracies compared to modern scanning technologies.

Adopting a Cutting-Edge Solution

When word spread about Flyability's development of the Elios 3—a rugged, indoor-capable drone equipped with LiDAR technology and advanced SLAM capabilities—mining engineers at the salt mine took notice. Given Flyability's proven track record in the mining sector, they decided to trial the Elios 3 to assess its potential for streamlining their stockpile measurement processes.

The goal was straightforward: leverage the drone's LiDAR sensor to accelerate data collection, enhance measurement accuracy, and eliminate the risks associated with climbing salt cones. By replacing manual methods with automated, high-resolution 3D mapping, they aimed to achieve faster, safer, and more precise outcomes across all aspects of their operations.

Transformation Through Innovation

The results exceeded expectations. During testing, surveyors successfully generated high-quality 3D models of multiple salt stockpiles using the Elios 3, demonstrating the system's effectiveness and versatility. Key takeaways from the pilot project include:

-

Time Savings: The Elios 3 dramatically reduced the time needed to collect comprehensive data for each stockpile. Instead of spending days climbing and measuring manually, surveyors could complete data acquisition in a fraction of the time.

-

Enhanced Accuracy: The LiDAR data produced by the Elios 3 offered unparalleled precision in stockpile volume calculations. Compared to traditional manual techniques, the difference in accuracy was striking, providing actionable insights for operational planning.

-

Improved Safety: One of the most significant benefits was the elimination of hazardous climbing tasks. Surveyors no longer needed to risk injury by ascending steep salt cones; instead, they operated the drone remotely from a secure location, ensuring their safety while capturing all necessary data.

-

User-Friendly Operation: Even novices found the Elios 3 intuitive to operate. Its stability and responsive controls allowed surveyors to master the drone's flight dynamics rapidly, enabling them to focus on data collection rather than mastering complex controls.

"I had zero prior experience with drones before trying the Elios 3, and I must say, it's incredibly user-friendly. Within a single day, I went from being unfamiliar with the equipment to confidently flying it and gathering valuable data. It feels solid, performs smoothly, and the interface is fantastic."

- Mining engineer at the salt mine

Future Potential

Encouraged by the positive outcomes of their pilot program, the surveying department at the salt mine is seriously considering adopting the Elios 3 as their primary tool for stockpile management. Transitioning to this technology would yield numerous advantages:

-

Achieving greater efficiency by reducing the number of man-hours required for routine tasks.

-

Improving data reliability through more accurate 3D modeling.

-

Enhancing workplace safety by minimizing exposure to risky environments.

Beyond stockpile evaluations, the Elios 3 holds promise for broader applications within the mine. The head of the surveying department envisions using the drone to create detailed 3D maps of the entire mine, moving beyond the current 2D plans. Such maps would offer unprecedented clarity and depth, empowering operators to make better-informed decisions regarding resource allocation, maintenance, and exploration activities.

With its combination of innovation, safety, and performance, the Elios 3 represents a game-changing advancement for the mining industry. As more organizations embrace this technology, we can expect to see increased productivity, heightened safety standards, and more sustainable practices emerge across the sector.

Car Diffuser Perfume,Car Smell Diffuser,Car Air Freshener Diffuser,Scentsy Car Diffuser

Guangzhou Chiyang Scent Technology Co., Ltd. , https://www.diffuserscent.com