Inspection Tools: A Guide to the Tools Inspectors Use in Their Daily Work

Inspection Tools: A Comprehensive Overview of the Instruments Used by Inspectors in Their Daily Work

Inspection tools play a crucial role in helping inspectors gather the necessary data to ensure proper maintenance of the assets they are examining—read this guide for an in-depth look at the various types of tools inspectors use.

Inspection tools are essential for inspectors to collect data effectively.

This data can include visual, thermal, or thickness measurement information. The exact type of data needed for an inspection depends on the specific requirements of the task, which in turn determines the types of inspection tools required for the job.

After collecting the data, inspectors analyze it to assess the condition and maintenance needs of the asset being inspected.

Inspection Tools vs. Inspection Equipment

For the purposes of this article, inspection tools refer to the actual instruments and devices inspectors use to collect data.

This could be a thickness measuring sensor that helps inspectors evaluate the thickness of a wall inside a coke drum, or it could be a drone with a camera that enables inspectors to collect visual data on the condition of a boiler from a remote location.

Inspection equipment, on the other hand, refers to anything that aids inspectors in accessing data or supports their work as they collect data. This could be the toolbelt an inspector wears, the scaffolding they stand on to manually collect visual data with the naked eye, or the ropes they use to climb or rappel inside an asset to collect the necessary data.

[Related read: Confined Space Equipment: A Guide]

No matter if it’s a large industrial boiler or a home HVAC unit, the fundamental concept of how inspectors use inspection tools remains consistent:

-

Inspectors collect data using inspection tools

-

Inspectors analyze that data using methods specific to the industry they are working in

-

Inspectors and/or maintenance personnel make a maintenance determination based on that analysis

While the overall idea is relatively straightforward, the types of inspection tools that inspectors use can vary widely. That said, they can generally be categorized based on the type of data they are used to inspect.

It’s worth noting that, in the case of robotics solutions, the manner of data collection (i.e., aerial or ground-based) is used to organize the tools rather than the specific type of data the tools capture. This means that drones and ground-based robots can sometimes be equipped with different sensors, allowing the same inspection tool to capture different types of data.

Now let’s take a closer look at each type of inspection tool.

Â

Cameras and Other Visual Data Collection Tools

In any field, visual data is one of the most common types that inspectors need to collect.

Of course, cameras are the go-to inspection tool for capturing visual data, but not all cameras will be suitable for a given inspection. The key criteria for choosing an inspection tool for visual data collection is the data requirement. If the camera you’re considering can collect the data you need at a quality that meets your inspection needs, then it’s the right tool for the job.

Here are some common types of visual data collection tools:

-

Digital cameras. Digital cameras vary greatly in terms of quality and cost, so it’s important to know exactly how precise your images need to be. Factors like the ability to work in low-light conditions or the need for high-quality color may also influence your choice when selecting a good digital camera as an inspection tool.

-

Borescopes. A borescope is a visual inspection tool consisting of a tube with an eyepiece at one end and a lens at the other. Borescopes allow inspectors to see areas that are otherwise inaccessible (see picture below).

-

Video and digital microscopes. Video and digital microscopes magnify images using digital technology. These types of microscopes allow inspectors to get up-close visual data, and typically come with high-powered lenses that render clear images, even of very small objects. Â

-

Videoscopes. Videoscopes give inspectors a way to see inside small cavities and other areas remotely. Their camera is embedded in the tip of the scope and uses CCD technology along with focusable lens assembly to relay images.

-

CCTV. Closed Circuit Television is often used for inspecting pipes, specifically for sewer inspections, because it allows inspectors to see inside pipes and drains remotely.

A borescope being used to inspect a car engine

A borescope being used to inspect a car engine

Other NDT Sensors and Testing Methods

Although visual data is the most common type of data inspectors need to collect, there are many other types that might be required to meet the requirements of a given inspection.

Each type of data an inspector needs will require a different inspection tool with a sensor made for collecting that data, or an NDT (Non-Destructive Testing) method that can collect the required data.

Ropes and Drones Case Study

A great example of inspectors using various types of tools and NDT methods to collect all the data they need can be seen in a recent inspection conducted by Premium Inspection & Testing, an inspection service provider based in Baton Rouge, Louisiana.

Inspectors from Premium needed to conduct a coke drum inspection without building scaffolding. To do this, they used a unique combination of drones and rope access so that they could leverage all the inspection tools required for the job.

Photo credit: Premium Inspection & Testing

Photo credit: Premium Inspection & Testing

Here are the steps the Premium team followed to complete the inspection:

1. Visual data collected by drone

Using Flyability’s Elios 2 drone, inspectors collected visual data inside the coker to ensure it was clean and to identify potential areas where they might want to focus their attention (see the next section for more information on the Elios 2).

2. Corrosion, pitting, and other data collected by rope access

Using rope access, inspectors performed other types of data collection inside the coke drum, including:

-

Creaform 3D scanning to determine the extent of surface pitting and corrosion

-

Phased array testing to test the integrity of the weld seams

-

Liquid penetrant testing to identify defects in the seams and shell

This mission highlights the ways that various sensors might be used during a single inspection in order to collect all the data needed to satisfy an inspection’s requirements.

It’s worth noting that this approach not only allowed inspectors to collect all the data they needed without using scaffolding, it also helped them save their client $250,000 in the process.

NDT Sensors and Testing Methods

Here are some examples of data inspectors might need which would require specific sensors or NDT testing methods:

-

Thermal data. Thermal data is collected with a thermal or infrared sensor. It can be used to help inspectors determine where heat is leaking out of a structure or where there might be an excess of heat inside a closed system.

-

Ultrasonic data. Ultrasonic data is collected with an ultrasonic sensor. This type of NDT testing uses sound waves to detect defects or imperfections on the surface of a material. Read our guide to ultrasonic testing to learn more about it.

-

Radiography data. Radiography testing is the act of using gamma- or X-radiation on materials to identify imperfections in a surface. Read our guide to radiography to learn more about it.

-

Eddy current data. Eddy current testing is a type of electromagnetic testing that uses measurements of the strength of electrical currents (also called eddy currents) in a magnetic field surrounding a material to locate defects in the material or make other inspection-related determinations about it. Read our guide to eddy current testing to learn more about it.

See our in-depth guide to Non-Destructive Testing for more information on NDT methods and data collection.

Robots

There are three primary categories for the robotics solutions (or tools) that inspectors use:

-

Drones / Aerial Robotic Solutions

-

Ground-Based Robotic Solutions

-

Submersible / Underwater Robotic SolutionsÂ

Drones / Aerial Solutions

Over the last several years, inspectors working in industrial scenarios have started using robots to collect inspection data remotely. Any tool that allows an inspector to collect data remotely falls under the umbrella term Remote Visual Inspection (RVI), and drones are quickly becoming one of the most common types of RVI tools.

Inspectors typically use drones to collect visual data, but some drones can also collect thermal data or even be outfitted with unique sensors that allow them to collect other kinds of data. As drone technology develops, the ability to use different kinds of sensors with them to enable new types of data collection will only continue to grow.

Why use RVI tools?

Here are the three biggest benefits to using a robot like a drone to collect inspection data:

-

Safety. By using a drone or other robot to collect data, you can reduce the need for a person to place themselves in hazardous situations to collect inspection data, such as standing on scaffolding, entering a confined space, or using rope access. Learn more about how indoor drones help companies improve safety.

-

Savings. Drones can reduce the cost of an inspection significantly, sometimes by as much as 90% or more. Savings are primarily realized from avoiding the need for temporary structures, like scaffolding, used in manual data collection, and also in reduced work hours and downtimes. Learn more about how indoor drones help companies save money.

-

Reduced downtimes. Because drones can significantly speed up the inspection process by avoiding the need for building and taking down scaffolding and the speed of data collection, using them can result in significant downtime reductions.Â

Indoor vs. outdoor drones

Indoor drones are inspection tools made for operating in confined spaces.

Flyability’s Elios 3 (shown above) is an indoor drone that sits in a cage, allowing it to collide while operating in confined spaces and continue flying. This kind of design was created with indoor inspection scenarios in mind.

Boilers, pressure vessels, and tanks are all examples of assets commonly inspected with an indoor drone, but there are many other types of assets that require a drone like this—check out our case studies to see all the different industries benefiting from the use of indoor drones.

Outdoor drones, on the other hand, are made for collecting inspection data outdoors, and don’t come with the same kind of cage or collision tolerance that an indoor drone has.

DJI's Matrice 300, an outdoor drone commonly used in inspections

DJI's Matrice 300, an outdoor drone commonly used in inspections

Ground-based Robotic Solutions

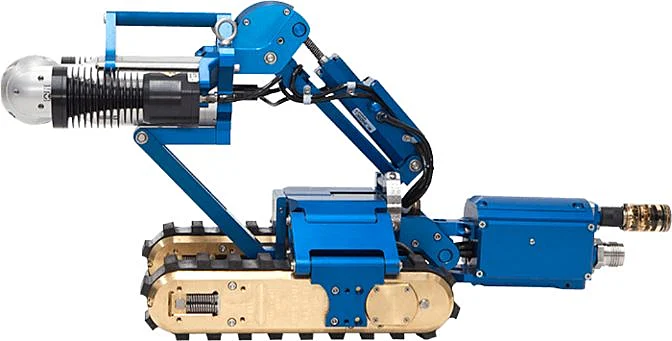

Another type of RVI tool that inspectors use to collect inspection data are ground-based robotics solutions—that is, robots.

Ground-based robots can provide the same kinds of benefits that drones do for inspectors, helping them increase savings while improving safety during inspections.

There are several different types of robots out there made specifically for inspection data collection—here are just a few examples:

Inuktun MaggHD

The Inuktun MaggHD is a miniature magnetic crawler used for remote visual inspection (RVI) in lieu of hazardous confined space entry (CSE) or working at heights.

Deep Trekker DT320

The Deep Trekker DT320 is a mini pipe crawler made for inspections inside sewer pipes and other small spaces that present challenges for manual data collection due to accessibility issues.

Inuktun Versatrax 150

The Inuktun Versatrax 150 is another type of crawler inspection system. It is configurable, designed for long range use up to 500 feet, and commonly used to inspect tanks and pressure vessels as well as wastewater infrastructure.

Robots—Submersible Solutions

One area seeing advances in RVI technology is in the area of submersible robotics. While more often thought of as exploration robots, these kinds of robots have also been providing inspectors with new ways to collect data.Â

As with other kinds of remote inspection tools, these tools increase worker safety by removing the risks inherent in diving operations. And, in some cases, providing inspections in liquid-filled areas that are not accessible to people otherwise. Â

MASKI+

The Maski+ remotely operated vehicle provides HydroQuebec access to locations where the water is too turbulent or deep for divers to safely inspect hydro dams. It features multiple cameras and an array of sensors.Â

INTERO TANK EXPLORER

One subset of submersibles are unique in that they are intrinsically safe robots, meaning that it can be used in explosive and flammable environments, like petrochemical storage tanks. One such robot is the Intero Tank Explorer which detects inconsistencies in the thickness of the tank and provides images—all while the tank is operational.Â

Recent Advances in Robotics

Inspections of the future will have a greater array of remotely operated tools from which to choose, including additional types of NDT sensors to use with them. For example, robot-mounted remote ultrasonic testing tools are useful in many industries.Â

In addition to those robotics solutions highlighted above, new robots are being designed to provide inspection data for locations that are otherwise hazardous or inaccessible, like aging sewage systems.Â

Some of these robots can even fix the defects they help inspectors identify using onboard tools like water-jet cutters to loosen debris and pipe patches that can be cured with UV light.

Measuring Devices

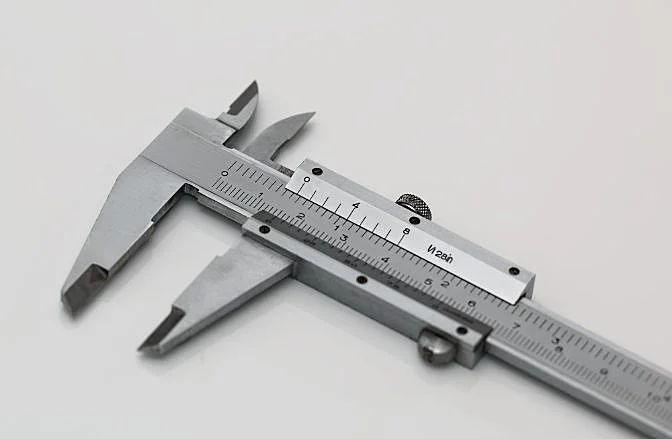

Measuring devices are a type of inspection tool that helps inspectors collect measurement data, such as how long, deep, or wide something is.Â

Although there are some sophisticated digital measuring devices, many of the most common measuring devices are hand-held tools that don’t require any electricity at all, like calipers (shown below).

Here are some of the most common measuring devices out there:

-

Engineering Square. Engineering squares help determine whether two surfaces are exactly perpendicular. They can also help draw straight lines.

-

Protractors. Protractors are used to measure the angle between two surfaces (angle gages also do this).

-

Levels. Levels measure the inclination of a surface relative to the earth’s surface. They range in complexity from fairly simple mechanical tools to sophisticated electronic sensors that can provide digital angular level values.Â

-

Calipers. Calipers typically rely on a precise slide movement for measurements. There are several different kinds, and they can be used to measure a variety of things, such as depth and length or external and internal dimensions. Calipers can also be used to compare or transfer dimensions from one object to another.

-

Gages. Gages are used to compare an object to a standard size. They can measure things like radius, thickness, angle, or bore size. A length gage is used to measure the length of an object, and a depth gage is used to measure the depth of holes.

-

Micrometer. A micrometer uses a gage to measure very small distances. It does this by placing a surface or object between its two faces and moving one of those faces closer or farther away by turning a screw with a fine thread.

Inspection Software

A growing challenge for inspectors is how to manage greater and greater quantities of inspection data.

That's why many of the most promising advancements in the inspection industry are in software development. Two areas in particular show special promise, refinements in data collection software and innovations in data management.

Improved Data Collection Software

As inspectors work with remote tools, their needs become more clear, and software developers are recognizing how to provide a more streamlined experience. For example, the Flyability Inspector 3.0 software includes proprietary 3D modeling software. When inspectors fly through an asset, the software creates a quick 3D model of the asset under inspection and indicates the defect's location.Â

Data Management Tools Â

New-generation software solutions can capture better and more data than can possibly be processed manually. Increased utilization of artificial intelligence (AI) and machine learning are helping inspectors process data rapidly to make it immediately usable.

At the moment, sewer inspection software companies are leading the way with solutions that allow users to upload visual data, which is then automatically sifted to identify potential defects.Â

Whether innovations or refinements, every piece of software that helps improve the speed and quality of inspections creates safer outcomes for everyone.

Â

Digital Welding Machine Equipment

MIG/MAG/TIG/MMA WELDING MACHINE:

The gas shielded welding machine actually has the characteristic of falling externally. It converts 220V and 380V AC into low-voltage direct current. Generally, the gas shielded welding machine can be divided into two types according to the type of output power supply, one is AC gas shielded welding machine; It is a DC gas shielded welding machine. The current conversion mode of the DC gas shielded welding machine is AC-DC-AC-DC. The gas shielded welding machine is composed of a power supply and a wire feeder. The shielding gas includes CO2, CO2 and argon mixed gas, and CO2 and helium mixed gas. do shielding gas

Features of gas shielded welding machine:

1 It has the advantages of light weight, small size, high efficiency and high reliability.

2 The welding current can output a rectangular pulse waveform to achieve spray transition and facilitate all-position welding.

3. It has automatic compensation function for grid voltage fluctuation.

4. It has automatic protection functions such as overvoltage, undervoltage, overcurrent and overheating.

5. Automatic compensation according to the cable length to ensure good welding performance for different cable lengths.

Precautions

1. Welding may cause fire or explosion

1.1 Protect yourself and others from sparks and weldments during welding;

1.2 Be sure not to perform welding where there are combustible materials, because splashing sparks can easily cause combustion and cause a fire;

1.3 Be alert to fire, and place a fire extinguisher in the welding area;

1.4 Do not use a gas shielded welding machine to defrost the pipeline;

1.5 When the equipment is out of use, please unplug the welding cable from the welding output terminal;

1.6 Before welding, the on-site staff should hand over all flammable and explosive materials such as matches and lighters.

2. Fume and gas generated by welding will damage health

2.1 Keep good ventilation when welding indoors;

2.2 Do not perform welding near the site where there is degreasing, cleaning or spraying operations, because the heat and rays generated by the arc can react with the water vapor in the air to produce highly toxic and irritating gases.

3. Heating parts can cause severe burns

3.1 Do not directly touch the heating parts with your hands;

3.2 It can be welded with a welding torch after cooling.

4. Arc rays can burn eyes and skin

4.1 When welding or watching, you must wear a helmet with suitable filters to protect your face and eyes;

4.2 Use welding shields to protect bystanders from interference and stimulation from sparks and strong light.

If you have any questions, please contact with us directly. Welcome you can visit our Factory.For inquiry, please send mail directly to us.

Digital Welding Machine Equipment,MIG Welders,Welder MIG,Double Pulse MIG Welder

JIANGSU FUERMU WELDING CORPORATION , https://www.fuermuwelding.com