What Is Destructive Testing and How Does It Work?

What Is Destructive Testing and How Does It Work?

Destructive testing is a method used to examine the point at which a component, material, or asset fails under various stress conditions. Inspectors apply different destructive test techniques to materials, causing them to deform or even destroy them entirely, to gather insights into how the material behaves under pressure. This testing helps identify crucial physical properties like toughness, hardness, flexibility, and strength.

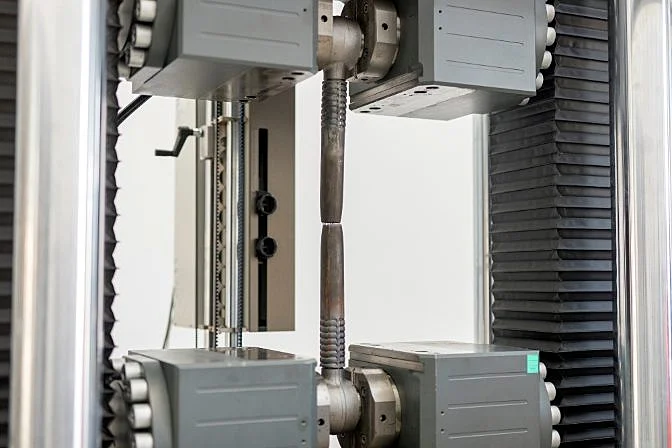

Commonly referred to as destructive physical analysis (DPA) or destructive material testing (DMT), this approach is vital for understanding the limitations of components. By identifying these limits, inspectors can make informed recommendations regarding appropriate operating, maintenance, and replacement practices. The images below illustrate examples of materials undergoing strength and durability tests.

Strength testing of metal samples | Source: DedMityay, iStock

These destructive physical analyses play a significant role in assessing the reliability of materials and components. They are often employed in failure analysis, process validation, and materials characterization. Additionally, destructive testing frequently complements non-destructive testing (NDT) methods, such as digital radiography, in engineering critical assessments.

What Is Destructive Testing?

Unlike non-destructive testing (NDT), which does not harm the material being tested, destructive testing intentionally subjects materials to conditions that cause deformation or destruction. This method is typically used before a component is mass-produced or put into practical use to predict its behavior under stress. In contrast, NDT is more commonly used for ongoing monitoring of assets already in operation to detect early signs of damage and prevent failures.

For instance, imagine a car manufacturer conducting destructive tests on the seat belts of a new model to ensure they meet safety standards under extreme conditions. Meanwhile, NDT might be used later to inspect the vehicle during routine maintenance to check for wear and tear on these belts.

[Learn more about NDT in our comprehensive guide.]

Which Industries Use Destructive Material Testing?

Destructive testing is usually carried out by in-house teams or outsourced to third-party providers. Many of these tests take place in specialized labs equipped with advanced tools. Industries relying heavily on destructive testing include:

- Aerospace

- Automotive

- Chemical

- Construction

- Defense

- Electrical Engineering

- Fabrication

- Infrastructure

- Manufacturing

- Oil & Gas

- Petrochemical

- Pipeline

- Power Generation

- Software

Destructive Testing Technicians

Professionals involved in destructive testing include:

- Chemists

- Electrochemical process experts

- Failure analysis specialists

- Material scientists

- Metallurgical and polymer engineers

- Quality control analysts

- Regulatory compliance officers

Destructive Testing Methods

Various destructive testing methods simulate real-world conditions to evaluate the performance of materials under stress. These tests help assess the strength, durability, and overall reliability of components. Some of the most common destructive testing methods include:

- Aggressive environment testing

- Corrosion testing

- Fracture and mechanical testing

- Fatigue testing

- Hardness testing

- Hydrogen testing

- Residual stress measurement

- Software testing

- Tensile (elongation) testing

- Torsion testing

Read on for detailed explanations of these destructive testing methods or click the links above to jump directly to each one.

Aggressive Environment Testing

This method evaluates the fatigue and fracture points of components when exposed to corrosive environments at varying pressures and temperatures. Simulated conditions mimic the operational environments of the components. Corrosive environments may include high salinity, humidity, hydrogen sulfide, carbon dioxide, and other natural elements.

Corrosion Testing

Corrosion testing assesses the point at which a component begins to corrode when exposed to saltwater or freshwater. The image below shows corroded pipes as an example of corrosion testing results.

Fracture and Mechanical Testing

Fracture and mechanical testing encompass several destructive tests, including:

- Bend Test: A quality control test that bends materials to expose embrittlement.

- Charpy Impact Test: A high-strain test that determines the energy absorbed during a fracture.

- Crush Test/Compressive Strength Test: Widely used to measure the strength of concrete under load.

- Weld Fracture Test: Designed to reveal imperfections in welds, such as cracking or porosity.

- Peel and Chisel Test: Determines weld size and failure type.

- Pellini Drop Weight Test: Measures the nil-ductility transition temperature (NDTT).

- Hydrostatic Pressure Test: Primarily an NDT method but can also exert strain within a material's elasticity.

Fatigue Testing

Fatigue testing determines the endurance of welded joints, base metals, and heat-affected zones under variable or constant loading conditions, typically in saltwater or open-air environments.

Hardness Testing

Hardness testing assesses whether a component undergoes permanent deformation under stress using the Rockwell scale. The degree of resistance to indentation determines the material's hardness. This test provides insight into how well a component will perform over time and how long it can remain in service.

Hydrogen Testing

Hydrogen testing exposes components at risk of corrosion to hydrogen at different strain rates and temperatures.

Residual Stress Measurement

Residual stress measurement quantifies the internal stress of a component and its effect on surface stress. Engineers analyze residual stress distribution using methods like neutron diffraction, synchrotron diffraction, and X-ray diffraction.

Software Testing

Software testing is performed by engineers to evaluate the quality of software, uncover failures, and mitigate risks before the product is ready for use.

Tensile (Elongation) Testing

Tensile (elongation) testing elongates or compresses a component to determine its strength. This test measures breaking strength, maximum elongation and compression, and tensile strength to calculate physical properties and identify materials capable of withstanding immense force.

Torsion Testing

Torsion testing applies twisting forces to assess the shear strength of a material before deformation occurs. The point at which the material succumbs to twisting represents its failure point.

Destructive Testing Examples

One of the most familiar examples of destructive physical analysis is crash simulations. Automakers and aerospace companies use destructive testing to evaluate the functionality of safety equipment under failure scenarios.

In aerospace, high temperatures and pressures are applied to cabins to ensure safety features like air respirators continue to function properly. Destructive testing is also used to assess the strength of safety glass. Sandbags are dropped from specific heights to simulate impacts, while fire is applied to test flame resistance.

Personal protective equipment (PPE) like coveralls, earplugs, full-body suits, gloves, hard hats, respirators, safety glasses, shoes, and vests undergo destructive tests to comply with IEC and ASTM standards. These tests involve exposing PPE to electrical arc simulations or open flames to determine the energy levels the materials can endure before failing.

Destructive physical analysis is also essential in determining suitable materials for industrial boilers, which operate under extreme pressure and high temperatures. This ensures the pressure and temperature ratings of the boiler align with safe operational parameters.

Tensile testing is employed to evaluate the strength of welds in construction materials. These tests ensure the structural integrity of both the weld and the entire building. For example, skyscrapers exposed to natural elements rely on materials and components validated through destructive testing to withstand expected conditions.

Rigging Swivel,Industrial Lifting Hooks,Rigging Straps,Rigging Hooks

JIANGSU RUIJIN SLING CO.,LTD. , https://www.cnsteelcable.com