In most industries, companies are struggling with soaring fuel costs, which are driving operational expenses up and making it increasingly challenging to sustain profitability. Fortunately, renewable energy alternatives like solar, wind, and tidal power are now readily available in the market, each with its unique advantages and constraints. Among these, solar energy stands out as the dominant form of non-traditional energy in India due to the country's abundant tropical sunlight for much of the year and its relatively low maintenance costs. However, before transitioning your plant to solar power, it’s crucial to evaluate all the factors that could impact your business.

**Is My Built-Up Real Estate Suitable for Solar Energy?**

Given India's position in the southern hemisphere, solar panels typically need to be positioned at an angle and oriented toward the southern sky. Does your roof already feature south-facing slopes? If so, you could save significantly, as you won’t need to invest in additional structures to achieve optimal panel positioning. Additionally, consider whether nearby tall buildings or other obstructions might cast shadows on your panels, reducing their efficiency. The longer your solar panels receive direct sunlight, the more effective your solar plant will be.

**Am I Prepared for High Initial Investment Costs?**

Once you’ve confirmed that your existing infrastructure is compatible with solar installations, it’s time to think about financing. Setting up a solar energy system requires a substantial upfront investment, but over time, its viability improves. In the first year, you’ll need to purchase and install panels that meet your energy needs, connect them to necessary equipment, and set up a monitoring and maintenance system. If your current buildings aren't ideal for solar panels, you’ll likely need to spend extra on customizing your rooftops or other open spaces near your business. Furthermore, if you’re planning to include solar-powered vehicle charging stations, factor in those costs as well.

**What Are the Key Components of a Solar Power Generation System?**

Solar panels are the primary component for capturing solar energy. Photovoltaic cells within the panels convert sunlight into DC power, which is stored in batteries. When you’re ready to use this energy, inverters convert it into AC power. Monitoring devices ensure the supply meets the expected voltage and frequency requirements. Additionally, a network of wires, switches, and protective devices is essential for safety and connectivity, both internally within your facility and potentially with the main power grid.

**How Can I Quickly Estimate Costs for My Solar Needs? Are There Any General Guidelines?**

Before committing to solar power, it’s vital to conduct a thorough feasibility study. Here are some rough estimates to help you get started. On average, India enjoys approximately eight hours of daily sunlight. Each hour of sunlight can yield around 300 watts of power, meaning eight hours of sunshine could produce 2,400 watts or 2.4 kilowatts (kW) per panel. If your plant requires 240 kilowatt-hours (kWh) of electricity daily, you’d need about 100 panels.

Each solar panel measures roughly 77×21 inches, occupying about 11 square feet of space. Thus, 100 panels would require 1,100 square feet. A general rule of thumb suggests that a 1 kW rooftop system needs about 10 square meters (around 100 square feet) of unshaded area. Therefore, a 240 kW system would require 2,400 square meters. However, actual sizing depends on factors like local solar radiation levels, weather conditions, panel efficiency, and roof shape.

If any of these factors, such as fewer than eight hours of daily unobstructed sunlight, are suboptimal, you’ll need more panels and space. Each panel typically weighs around 20 pounds (9 kilograms), so 100 panels would weigh approximately 2,000 pounds or nearly one ton. Ensure your building has sufficient structural capacity to support such a setup.

**Are There Subsidies or Government Programs to Support Me? How Do They Work?**

If you’re prepared to take the plunge into solar energy, there are numerous government incentives and subsidies designed to make the transition feasible and profitable. States and union territories are categorized differently for subsidy purposes. For instance, if you’re in a "general category" state, you can expect a 30% subsidy based on the installation cost. In special states, you may qualify for up to 70% of the benchmarked installation costs. Regardless, you’ll still need to cover the initial investment. Some state-level nodal agencies also offer additional support through specific programs. Additionally, state electricity distribution companies can purchase excess power from you, boosting your revenue streams. For more information on available subsidies and government initiatives, click here.

---

**Some Related Posts You Might Find Interesting:**

1. How to Save Money with Solar Panels? Read More.

2. Is Your Home Ideal for Solar Panels?

3. What Are the 5 Benefits of Solar Energy for Your Home?

4. Thinking About Installing Solar Panels? Here Are 7 Things You Should Know.

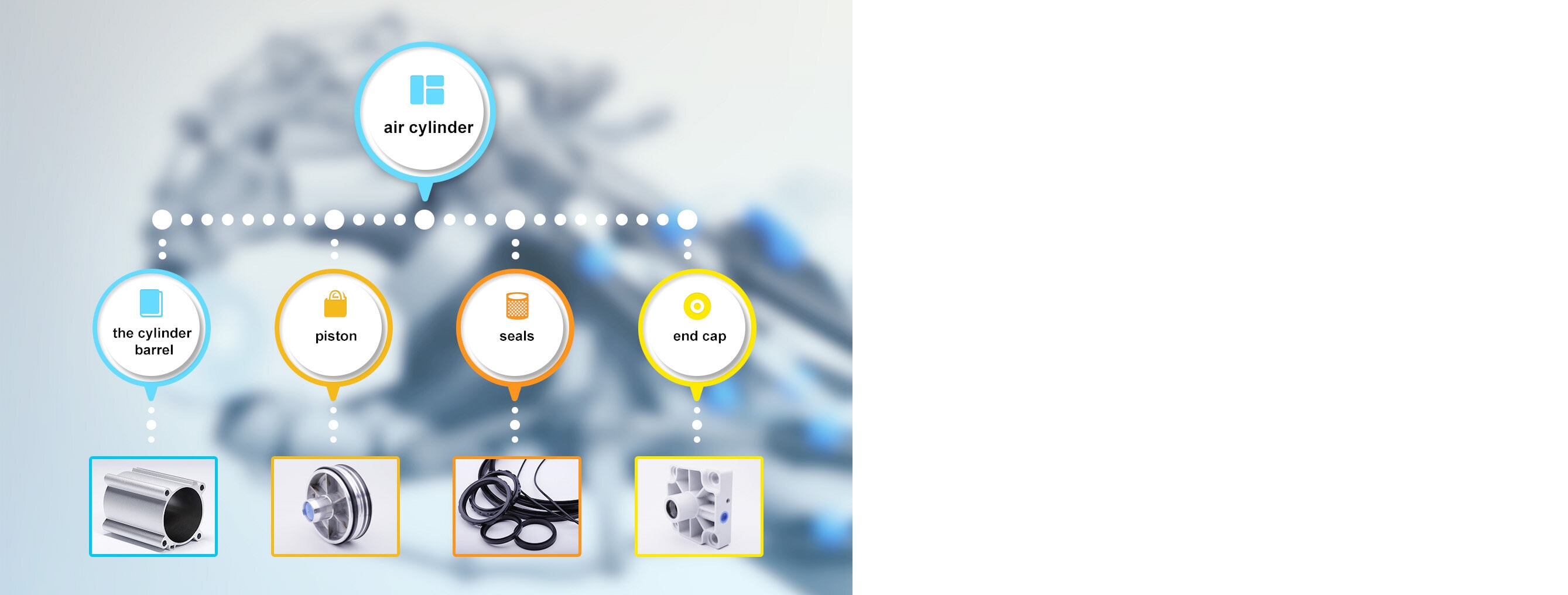

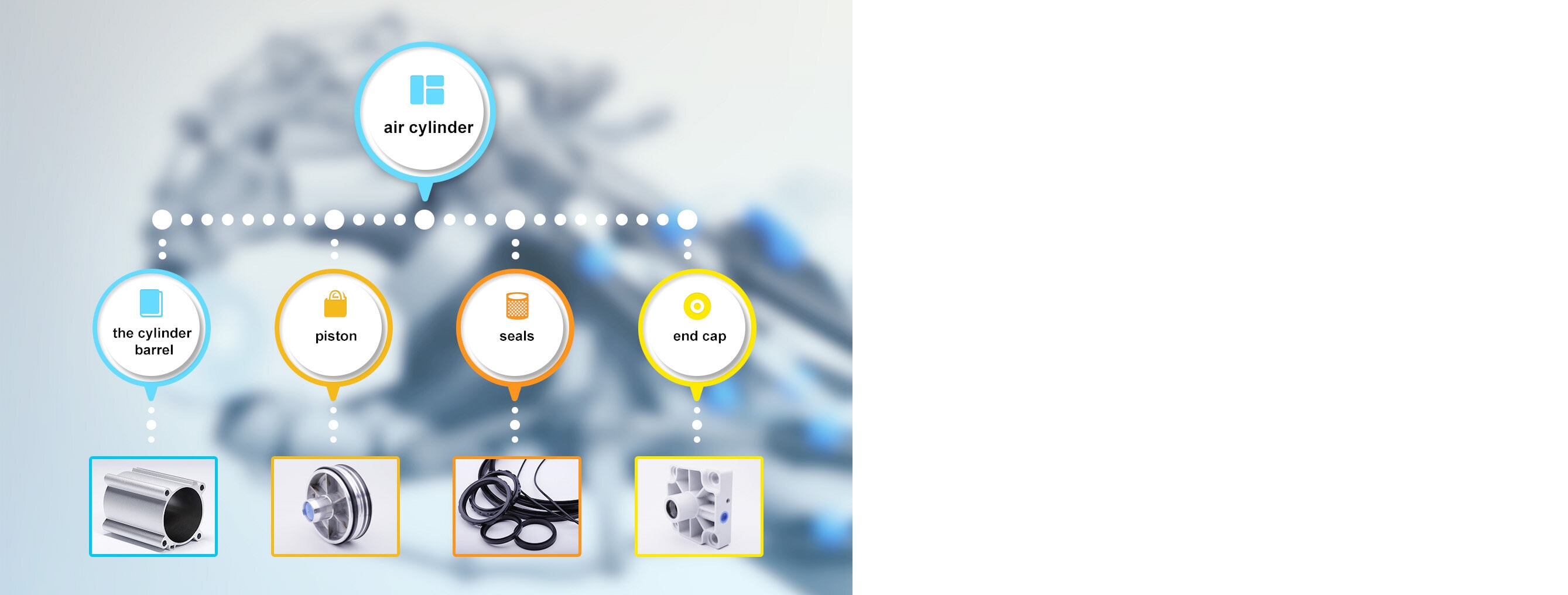

Pneumatic Cylinder

A pneumatic cylinder is a mechanical device that uses compressed air to produce linear motion. It is commonly used in manufacturing, automotive, and construction industries to power a variety of machinery and tools.

Air Cylinder Barrel.

The basic components of a pneumatic cylinder include a cylinder body, a piston with a piston rod, seals, and an air supply. When compressed air is supplied to the pneumatic cylinder, it pushes the piston, causing the piston rod to move.Pneumatic Cylinder Barrel.

Advantage of pneumatic cylinder

Compared to other types of cylinders or power sources, pneumatic cylinders have the advantages of being cost-effective, easy to operate, and requiring minimal maintenance.Pneumatic Cylinder.

Principle of pneumatic cylinder

The working principle of a pneumatic cylinder is that compressed air enters the cylinder body, pushing the piston to produce mechanical motion or force. Its efficiency and effectiveness can be evaluated by calculating the relationship between the work and energy of the pneumatic cylinder, which is governed by the laws of thermodynamics.

A key principle of pneumatic cylinders is the relationship between pressure and motion. The force produced by the cylinder body is proportional to the air pressure supplied to it. This means that increasing the air pressure will cause the pneumatic cylinder to produce a greater force.

Categories

Pneumatic cylinders can be divided into single-acting cylinders or spring return cylinders and double-acting cylinders. Commonly used cylinders include DNC and SI series ISO 6431 standard cylinders, SC standard cylinders, and stainless steel miniature cylinders.

Application

Pneumatic cylinders are widely used in automation and control systems to compress and release gas or liquid to achieve the conversion of force and motion. They are used in manufacturing for assembly lines, in construction for heavy machinery, and in the automotive industry for braking systems, among other applications.

Cylinders play a crucial role in modern industrial and mechanical fields. If you want to learn more about cylinders and their benefits in applications, please contact us. We offer a range of articles, videos, and other resources on cylinders to help you better understand their working principles and application scenarios. Whether you are an engineer, technician, or ordinary consumer, you can benefit from this information.

We believe that by gaining a deeper understanding of cylinders, you will be able to better understand the technology and applications in modern industrial and mechanical fields.

Pneumatic Cylinder,Air Cylinder,Pneumatic Air Cylinder,Aluminum Pneumatic Cylinder

Foshan Weiyingjia Technology Co., Ltd , https://www.wyspneumatic.com